Uyilo olukhethekileyo lweephedi zeerabha zesiko

Xa uvelisa ikhiphedi ye-silicone yesiko, nikela ingqalelo kwindlela izitshixo zakho eziza kubhalwa ngayo okanye ziphawulwe. Uyilo lwephedi yezitshixo ezininzi alufuni kuphawulwa, njengephedi yezitshixo eziya kubanjwa endaweni yi (ebhalwe) ibhezel yolunye uhlobo. Nangona kunjalo, uninzi lweephedi zamaqhosha zifuna uhlobo oluthile lokumakisha ukuchonga imisebenzi yesitshixo ngasinye. Unenani leenketho ezahlukeneyo xa kufikwa kwindalo ephambili, nganye ineenzuzo zayo ezizodwa.

Ukushicilela

Ushicilelo yeyona ndlela isetyenziswa rhoqo yokumakisha i-silicone kunye neephedi zerabha, ikakhulu ngenxa yokuba inexabiso eliphantsi kwaye iguquguquka kakhulu ngemibala kunye neemilo ezisetyenzisiweyo. Ngexesha lenkqubo yoshicilelo, iphedi yamaqhosha iyacandwa ukuze umphezulu woqhagamshelwano womshicileli uleyibhelishe umphezulu wesitshixo. Ngokuxhomekeke kwigophe lezitshixo ozifunayo, unokukwazi ukuprinta yonke indlela ukuya kumda weqhosha ngalinye. Ungaphinda uprinte ugxininiso olungakumbi kumaziko.

Izitshixo eziprintiweyo zitshiphu, kodwa zikhawuleza ziphele. Ngokuhamba kwexesha umphezulu wesitshixo ugxothwa ngokunikezela, kwaye indawo eprintiweyo iyaphela. Kukho iindlela ezimbalwa zokwandisa ubomi bezitshixo eziprintiweyo.

1. Iiplastiki zokuphela kwee-caps zinokuthi zifakwe ekupheleni kwesitshixo ngasinye, ukunika izitshixo ukuthungwa okuyingqayizivele, ngelixa ukhusela indawo ephambili kwi-abrasion.

2. Iingubo ze-oyile ezingaphezulu kwezitshixo zinika izitshixo ukugqiba okukhazimlayo. Bakwandisa ubomi bokushicilela.

3. I-drip coating kunye neengubo zeParylene zifakwe phezu kwezitshixo emva kokushicilela. Oku kuvelisa umqobo phakathi kwendawo eprintiweyo kunye nomsebenzisi ngaphandle kokufuna i-cap yeplastiki. Iingubo zandisa ubomi bezitshixo, kodwa kuya kufuneka ujonge ukunyamezela kokusingqongileyo kwengubo ngaphambi kokuba uzisebenzise kwezinye iimeko.

Ukuqhafaza kweLaser

Kwi-laser etching, umphezulu werabha ye-silicone uphathwa ngedyasi e-opaque ephezulu ehonjiswe ngelaser ukuyila uyilo. Ukuba uqala ngomaleko wesiseko oguquguqukayo, oku kunokuba bubuchule bokuleyibhela obuluncedo kakhulu ukwenza ikhiphedi ye-silicone ekhanyiswe ngasemva. Ukukhanya kuya kukhanya kwileyibhile ngelixa ivaliwe yinto eseleyo yesitshixo, idala isiphumo esibonakalayo esiluncedo. Iinketho zokwaleka kunye ne-capping ziyafana kwi-laser etching. Nangona, ekubeni ileyibhile ingekashicilelwa, ayinyanzelekanga.

IiCaps zePlastiki

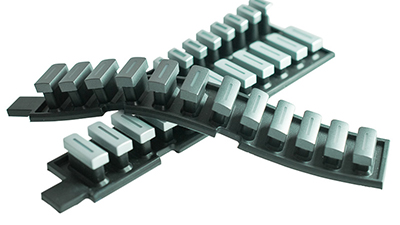

Iminqwazi yeplastiki kufuneka isetyenziswe kwiimeko apho ubomi obude bekhiphedi buyimfuneko. Iminqwazi ephambili yePlastiki inokuthi yenziwe ngamanani / iilebhile ezibunjiweyo kumphezulu wazo, okanye kunye nokudandatheka okanye iiplastiki ezinemibala eyahlukileyo.

Iminqwazi yeplastiki isesona sisombululo sibiza kakhulu kwingxaki yokubhala iilebhile. Kodwa zikwalungele iimeko apho iphedi yezitshixo iya kubona ukusetyenziswa okuninzi kangangokuba ushicilelo oluqhelekileyo aluyi kusebenza. Ukuba ufuna ukusebenzisa iminqwazi yeplastiki kwiiphedi zakho ze-silicone, qiniseka ukuba iplastiki oyisebenzisayo ayihambisani kwaye iya kuma kumaqondo obushushu afanayo nawo onke amaqhosha e-silicone.

Iingqwalasela ezongezelelweyo

Xa uthatha isigqibo malunga nohlobo lweleyibhile yezitshixo zakho, qiniseka ukubabonisanakunye nabaqulunqi kunye neenjineli eziqeqeshiweyo kwi-JWT Rubber. Siza kusebenza nawe ukufumana ulungelelwaniso phakathi kobomi obuphambili kunye nokusebenza kakuhle kweendleko.

Ukulayita ngasemva iqhosha leRubber

IPlastiki kunye neRubber Keypad

Isisombululo sekhiphedi yeRubber yesiko

PU ukutyabeka

Isixhobo sokufaka i-JWT Laser

Iphedi yeRubha yoShicilelo lweSilk

Ixesha lokuposa: Jul-05-2020